white label Tearing Resistance Testing|Understanding the Tearing Resistance Tester: An In : import At present, the most commonly used method of fabric tearing strength test is mainly the pendulum method, tongue method and trapezoidal method. Aside from these three . Acompanhe o retrospecto e classificações de Linfield em Campeonato da Irlanda do Norte 2023/2024 e veja o desempenho do time na temporada analisando a tabela .

{plog:ftitle_list}

VIDEO DO MENDIGO. Ruivinha vzd 14 😈🔥. Nossa esse vazado 😈. Vazado muito louco 😈 🔥. Loirinha vazado 1 🤤🔥. CUPHEAD DE GRAÇA 🤙🏼. GTA 5 ISO. CRIE SEU NFT 💸💰. Pior video vazado 1 😈🔥.

A tearing resistance tester is specifically designed to measure the force required to propagate a tear in a sample material. This measurement is crucial for determining the durability and suitability of materials under real-world conditions.The Elmendorf tear tester measures tearing resistance by calculating the force required to propagate a tear through a material sample. Why should I choose the SLD-01 Tear Tester? .

ASTM D1424 and ISO 4674-2 are two essential standards for tearing strength testing, supplying standardized strategies for assessing the tearing resistance of fabric and . At present, the most commonly used method of fabric tearing strength test is mainly the pendulum method, tongue method and trapezoidal method. Aside from these three .Tear resistance in textiles involves the load required to propagate a single “rip-tongue” type of tear (tear coming from a cut). Typical graph showing a tear resistance test: We provide force .

TEAR TEST. Tear test determines a material's resistance to tearing forces, often encountered in applications involving thin films, fabrics. See more. PEEL TEST. Peel testing evaluates the strength of adhesion between two materials, . White-label DNA testing services provide businesses the opportunity to offer genetic testing under their own branding. This enables companies to expand their product lineup without the need to develop the tests in-house. DNA testing services have become crucial in various fields, including healthcare, ancestry, and personal wellness. .Packaging testing refers to the systematic evaluation and analysis of packaging materials, components, and the overall packaging systems, including primary, secondary, and tertiary packaging, to ensure their effectiveness, safety, and .

Certain fibers and weaving methods result in fabrics with inherent abrasion resistance. Let’s look at how testing can reveal how different fabrics can hold up best along with time. Skip to content +86 769 2329 4842 [email protected] search Search. Menu. Home; . tears, and damage. It is one of the key durability factors in determining how .So buyers get an at-a-glance indicator of durability from the EN 388 label. Abrasion Performance Levels. While EN 388:2003 used fixed parameters, EN 388:2016 tailored the variables to modern materials in the upgraded test. . The EN 388 tear resistance test simulates such stress to gauge material fortitude. Tear Resistance Testing. When it comes to textiles, tear strength is a crucial factor in determining the durability and quality of fabric. It refers to the resistance of a fabric to tearing under stress or force. Properly measuring tear strength is crucial for textile manufacturers, designers, and quality control professionals. It ensures that their products meet industry standards.

For example, with rubber, tear resistance measures how the test specimen resists the growth of any cuts when under tension, it is usually expressed in kN/m. [2] Tear resistance can be gauged via the same ASTM D 412 apparatus used to measure tensile strength, modulus and elongation.ASTM D 624 can be applied to measure the resistance to the formation of a tear .

Understanding the Tearing Resistance Tester: An In

White Type 3 2.0 mil Satin White Type 3 Designation Units TUT10BG3 TTR10BG3 TWH15BL3 TWH20BS3 Test Method Physical Properties Area Factor ft2/lb m2/kg 140 28.7 140 28.7 87 17.8 60 12.3 — Ultimate Tensile Strength, Min. (MD) kpsi MPa 13 90 13 90 8 55 9 62 ASTM D-882 Tensile Modulus (MD) kpsi MPa 310 2,138 301 2,075 305 2,103 385 2,655 ASTM D .Tearing Strength Tester. Tearing strength testing can be found in plastic film, paper and textile industries. It is used to describe how well a material can withstand the effects of tearing. Elmendorf tear is a common method that is used to test tear resistance.This Complete Guide of the Elmendorf Tear Testing explores tear resistance testing dimensions, application areas, standards, methodologies, troubleshooting, and the future landscape of tear analysis. Key takeaways and practical insights empower informed decisions in material science. Application of Elmendorf Tear Testing in IndustryTear resistance testing can be found in plastic film, paper and textile industries. Tear resistance is the measurement of a sample’s ability to resist tearing. Tear resistance can be impacted considerably by the speed of the test, e.g. test speed used in generate the tear. Tear propagation resistance for the purpose of acceptance testing is .

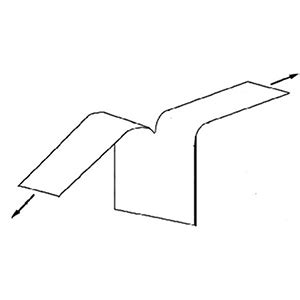

The testing method uses the principle of conversation of energy, which measures the energy consumed to test the tearing of a specific length of fabric. (Fall of Fan-shaped pendulum and potential energy consumed). The energy will be converted into the strength of tearing, which is the average tearing strength of the process of tearing.The 90-degree peel test is a method for calculating the unit force required to tear apart bound materials at a 90-degree angle. It can be used to examine the binding between a flexible material and a hard substrate. . ASTM-D5170 Standard Test Method for Penetration Resistance of Stretch Wrap Film (‘Peel Cling’ Method) Peel adhesion of .

1.2 It is not suitable for determining the cross-directional tearing resistance of highly directional boards and papers. These materials are covered by TAPPI T 496 “Cross Directional Internal Tearing Resistance of Paperboard.” 1.3 For edge-tear resistance see TAPPI T 470 “Edge Tearing Resistance of Paper (Finch Method).” 2. Summary

The tensile strength of a material is the maximum mechanical tension it can withstand before it cracks. It is given in N/mm² or MPa. The tear resistance of a material, also called tensile strength at break, is the mechanical tensile stress .Purpose of a tear test: The overall goal of a tear test is to determine a materials ability to resist the growth of the initial tear or its “tear resistance”. The value of a material’s tear resistance is generally accepted to be the force required to complete the tear so that it has gone completely though the material so that it has been . One way to measure tear resistance is through the Pendulum Method or Elmendorf Tear Test, as defined by ASTM D1922. The Elmendorf Tear Test is a simple and reliable way to measure the force required to propagate a slit in a plastic film a fixed distance to the edge of the test sample. The test is performed using a pendulum impact tester, which .ISO 6383-1:2015(E) 8 Number of test specimens 8.1 A minimum of five test specimens shall be tested in each of the required directions of testing. 8.2 Specimens which show a tear out of line to the extent that the tear reaches one of the edges of the test specimen shall be discarded and further specimens tested (see 11.3). 9 Speed of testing

This article outlines 7 major areas of testing for rubber, elastomers and polymers in general, broken down into 30 individual test methods and procedures. For more information on any of the instruments featured in this article, follow this links at the bottom of the page.D4576-16(2021) Standard Test Method for Mold Growth Resistance of Wet Blue and Wet White . D7584-16(2021) Standard Test Method for Evaluating the Resistance of the Surface of Wet Blue and Wet White to the Growth of Fungi in an Environmental Chamber . D7674-14a(2021) Standard Test Method for Hexane/Petroleum Ether Extract in Wet Blue and Wet WhiteTearing Resistance: Tearing resistance/ strengths is the ability of the paper to withstand any tearing force when it is subjected to. It is measure in both MD & CD, expressed in mN (mili Newton). Tear Factor: TAPPI standards require that the tear factor be expressed in units of dm 2 .Material between those two extremes has been shown to reliably use ASTM D1004 to compare tear resistance between materials. Materials Testing System. Due to the low forces involved in ASTM D1004 testing, we recommend a single column test frame such as Instron’s 68TM-5 or 34TM-5. Labs performing multiple test types on a single testing machine .

A tear starts with a snag on clothing etc., then the fabric has a small cut in it, so if the force continues the fabric will then tear. The cut before testing is to help with tear propagation. Q: What type of load cell to use and calibration certificate to request if we have test fabrics with tear strength between 10 and 100 newtons?Flame resistance Fabric’s ability to resist burning Note: Test is dictated by the intended end use for the fabric. Flame resistance Fabric’s ability to resist burning Crocking resistance Fabric’s colorfastness and ability to retain color is various conditions Ultra-violet light resistance Fabric’s resistance to fading when exposed to light

Elmendorf Tear Tester. Tearing strength testing can be found in plastic film, paper and textile industries. It is used to describe how well a material can withstand the effects of tearing. Elmendorf tear is a common method that is used to test tear resistance.{{blog-form}} #7 – Scuff Resistance Test. WHAT: Check durability of printed or painted boxes to resist abrasion; WHY: To ensure printed text on cardboard box can sustain rubbing, wearing; Printing is an integral part of packaging. With different types of printing methods being used, it’s important to check how well labels or prints can handle scuffing or abrasion. The most significant change to EN388:2003 was introducing the new “TDM-100 test” to measure the cut resistance alongside the coup test. The TDM-100 test is an ISO 13997:1999 cut test method, similar to the ASTM F2992-15 test method used in the ANSI/ISEA 105:2016 standard. This resulted in more accurate and reliable test scores.

Test Standards and Test Methods of Tear Strength

25 de out. de 2023 · Boteco Boa Praça Brasília. CLS 201 – Bloco C, Asa Sul. Terça a sexta-feira, das 17h às 2h. Sábados, das 14h às 2h. Domingos, das 12h à 0h. Menu .

white label Tearing Resistance Testing|Understanding the Tearing Resistance Tester: An In